Back

Back

'07 BMW G650 XCountry

Problem: FARFS ! ...or... Floppy-Ass Rear Fender Syndrome !

Mod: Add support for floppy rear fender:

The Bottom Line:

Here is my FARFS mod, a pair of black powder coated support brackets made out of aluminum plate that each mount to the frame and fender in 4 places:

The problem:

The rear fender mount is WAY too floppy and unsupported and in my case got grabbed by an aggressive rear knobby and was ripped off.

Of course there are many ways to do a MUCH simpler tail tidy that removes all the bulk and this works fine of course!

However, for myself, one of my first mods was a safety mod to mount the extra bright Whelen LIN3 LED brake light like AdvRider Drone has.

I did not want to lose this great brake light mod so my solution was to add support for the rear fender.

Since the LED brake light replaces the big bulky OEM license plate light, I now light it with 2 little license plate bolt LED lights.

I also didn't want the big bulky mud flap since I live in a dry area, so I removed it (big mistake!).

At this point the rear fender looked like this, but only 10 miles into my first off road trip on the White Rim Trail in Moab it ripped off, dangling by the license plate LED wires:

My XCountry had FARFS *really* bad! And I have the '07 Xco with even longer travel than the '09 !

Conditions: I had the stock Sachs shock with preload cranked up to its MAX and a 190 lb rider with no luggage.

I noticed that the shock would bottom on the first tiny little water bar you dare to just lift the front wheel over going 30mph.

I believe the fender ripped off for 3 reasons:

- The fender is way too unsupported and flops around.

- The OEM shock is way too soft for aggressive off road riding, undersprung with poor preload and damping. When it bottoms so HARD, the force really "flops the fender down".

- The final straw was the combination of the knobby tire AND the fact that I removed the big mud flap which exposed a sharp edge for the tire knobs to grab onto.

The solution:

After some creative brainstorming with Bruce, the helpful and hands-on owner of my local Kawasaki shop, we concluded that:

The fender assembly itself is rigid enough, but the FARFS is caused by the mounting of the fender to the frame not being solid at all - it just wiggles around too much.

If this mounting could be beefed up then the end of the fender would not move around so much. (Of course lightening it up would help also).

So we looked at various ideas and this below is what we came up with, basically using aluminum sheet stock and cutting out properly shaped support brackets:

I decided to cut out supports that would mount under the 2 grab bar mount holes and attach to the fender.

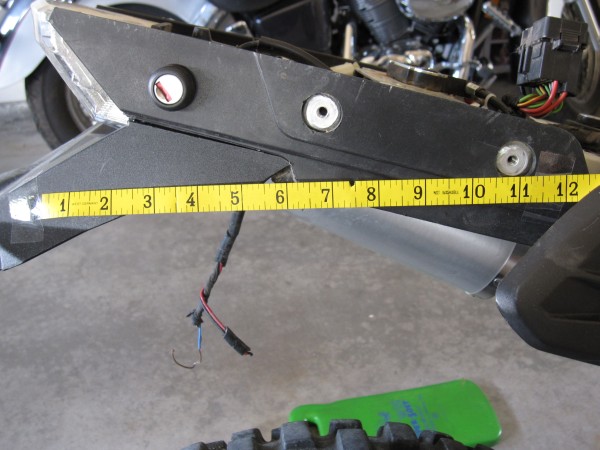

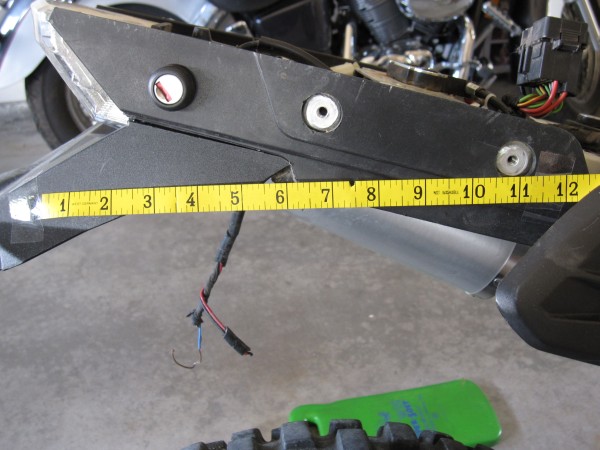

First I made a template. I had a great idea of putting up a (cloth sewing) tape onto the area before taking a picture of it.

Then use any software program that shows inch scales along the sides for height and width (like MS Word). So then you just resize the picture until the dimension on the tape measure matches that of the image before you print it out.

New: HERE IS THE TEMPLATE so you can download and print the template yourself. Just resize it when you print it until the ruler printed out matches actual dimensions. An easy way is to insert the photo into a Word document and resize the image. As shown in the printout, the template is for the left side of the bike and has a cutout area shown which is for the muffler mount. Use the same template for the right side just don't cut out the semi-circular cutout area.

Then using 1/16" thick aluminum sheet I cut it out with a jigsaw, drilled the 2 holes for the frame grab handle, and bolted it up. Then pulled up the fender tight, marked and drilled the 2 rear holes that go into the fender itself with stainless screws:

You can paint them black, however I was having black powder coating done on other parts so I had these powder coated black as well (I have a local shop who will do small jobs for $30 if you wait a couple weeks for the next time they are setup for it anyhow - contact me if interested).

The final installation can be a bit tricky, in my case I have the small-ish BMW rear tail rack which attaches to both sides of the bike at once so you have to use spacers (that came with the rack) and squeeze the support brackets inside there without scratching them.

It is MUCH easier to install if you still have the OEM grab bars to attach, or anything that only attaches to each side independently.

Also, the '07 with the aluminum subframe seems to have smaller diameter bolts (M6) than the '09 with the steel subframe does (M8), and the 07 bolts just don't feel that solid!

When I first removed the bolts there was a bit of galling of the stainless bolts in the soft aluminum, so I chased the threads with a tap to clean them out, then actually used anti-seize when I put the bolts back in, and was CAREFUL TO NOT OVERTIGHTEN THEM !!! But I do NOT carry heavy loads on my rack, so be careful if you do!

A side problem: Installing a replacement fender for an '07 with the latch mechanism:

Being an older build (from 12/06) I understand the older models of all 3 GX bikes have the rear fender held on partly with a pin in the top that goes into a latching mechanism.

To remove the fender you remove all the bolts then pull a cable under the seat that releases the latch holding the fender pin.

Not only is this latch a real kludge and does not provide a solid connection, but IF YOU HAVE TO ORDER a replacement "rear fender assembly / license plate holder", you may have the same problem I found... It didn't have this locking pin that I need.

BMW part number: 46627696760. My BMW dealer and the Atlanta BMW dealer I called, couldn't get an answer from the BMW parts hotline. There are parts at the warehouses in Stockton,CA and Nazareth,PA and a lot in Germany but they couldn't figure it out.

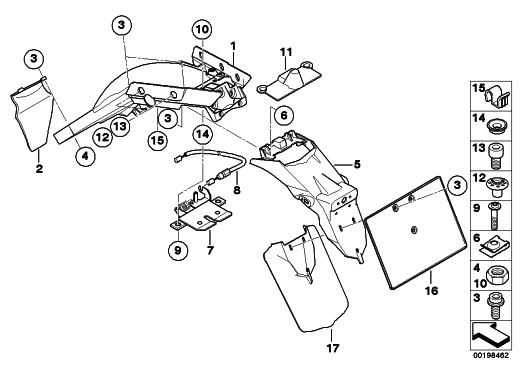

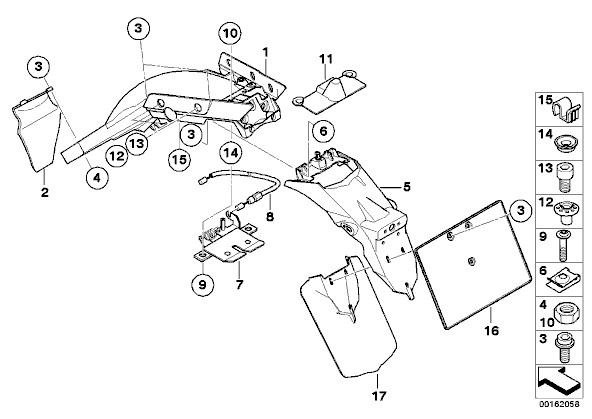

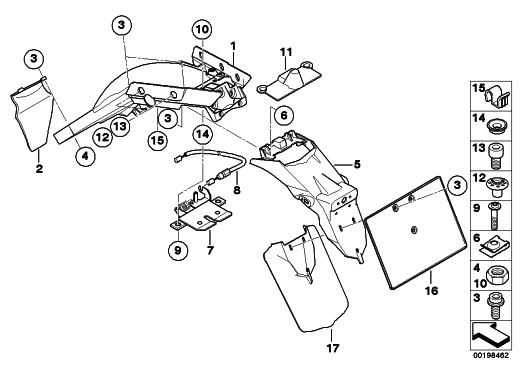

The BMW dealers' microfiche looks like this first one from section 46 at MaxBMW and it does NOT show the pin (item 5).

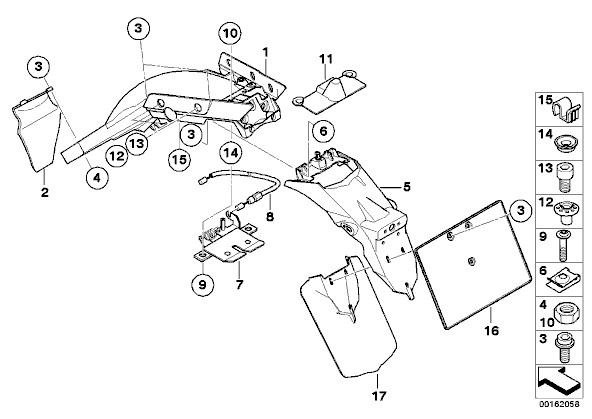

But the 2nd microfiche from RealOEM.com in fact DOES show the pin. But both use the same part number:

Here is a picture of the new fender I ordered on the left and my old one on the right with the pin. And NO you cannot remove the pin and move it, it is molded into the plastic and does not protrude below it. Using vise grips did not budge it.

In the end I figured out you cannot order a new fender with the pin in it, so I just customized it.

In the new fender plastic, I drilled out a hole where the latch pin should have been.

Then I removed the entire old latch assembly from the bike and instead I bolted in a little aluminum plate to fit the space, and epoxy'ed a nut onto it.

When bolting the fender onto the bike I added an additional screw and washer that goes into the new epoxy'd nut.

(Every little bit helps but you still need the new support brackets.)

Movies!!!

Here is a little video I made showing before and after the FARFS solution. The turn signals will of course still wiggle, and the mud flap still wiggles some but maybe about 1/10th as far, and it won't show what a big hit like a jump will do, but anyhow check it out!

Testing results:

After 6 months and a few rough 4WD road trips including all the passes around Telluride, CO, and even the LAB2Vegas where I broke my swingarm, resulting in my ass end of the bike sitting on the knobby going 70mph and burning molten fender plastic everywhere... no issues at all with FARFS! and this mod has held up very well with no issues!

After the Telluride trip I also installed a new Wilbers shock which makes a HUGE difference and no more bottoming out on small bumps.

On rare occasions I have thrashed the bike, catching air on water bars on trails and have bottomed the fork a lot, and even the Wilbers some, but no issues with the rear fender.

HOWEVER, I am too chicken to remove my extended mud guard on the fender, as I think it may still be part of the solution! HeHeHe!

Back

Back

Back

Back