Back

Back

'07 BMW G650 XCountry

Mod: Add 2 LED auxiliary lights:

This mod was prompted by the fact that I burned out two H4 headlight bulbs within one week. I think it was related to my Yuasa battery starting to get old (<2 years old) but nonetheless I did not like the idea of being stranded without a light on a trail somewhere.

Since the LED lights are very cheap and use very low current I thought they would be a perfect way to supplement the lighting.

This mod supplies bright light at night and also act as more conspicuity during the daytime.

Solution:

I bought 2 of the Model 30 LED lights from AdvMonster.com which are sold by Adv inmate sanjoh and more discussion is on his Aux Light thread.

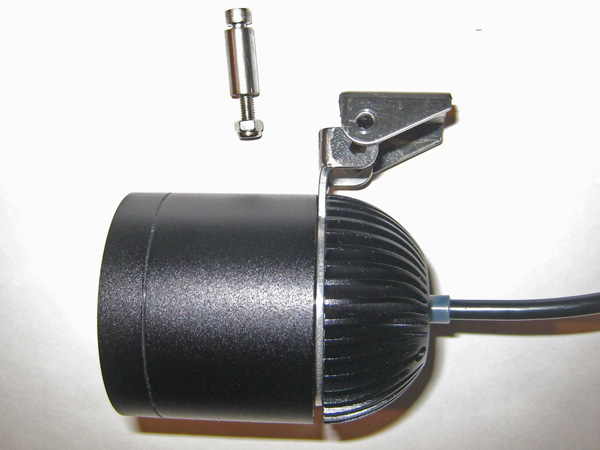

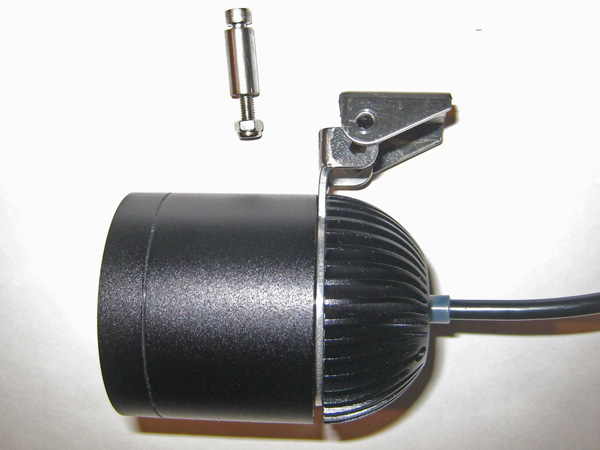

I paid about $60-70 each and I recommend getting the heavy duty bracket for $10 more each light and also the $5 Xpel clear lense protector. Stock photo:

Although he sells other brighter lights, I picked this model because it is spec'd to only use 0.85 amps each at full power so it wouldn't add much of a load onto the circuit, yet it outputs 1500 lumens each.

In fact I measured the actual amps for 2 of the Model 30 LEDs to be 1.4 amps when on fully. (Measured with a handy $13 fuse circuit tester from Harbor Freight).

The Model 30 is a spot light and I would have preferred a flood but for the price I just got it.

Here is sanjoh's explanation of new and old models.

The early models sanjoh sold reportedly had quite a few failures. I personally believe this was due to running the drivers at a very high current to achieve the most light output.

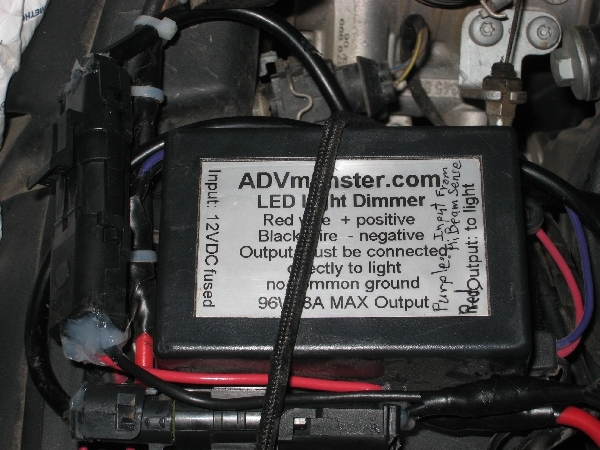

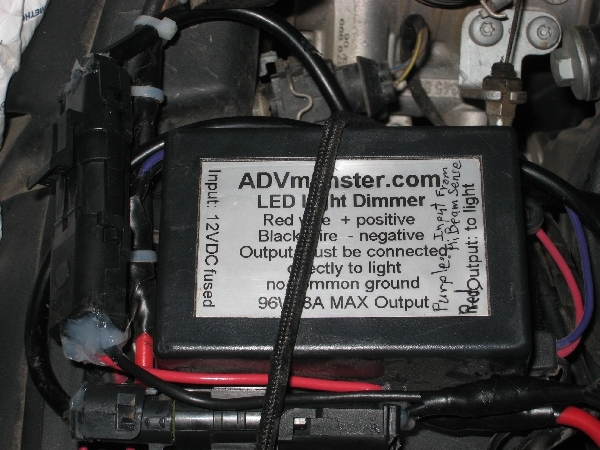

My solution to this is to also install his $45 LED Dimmer module which is waterproof and has a wireless remote control fob. It also has a high beam bypass control input that I wired to my high beam so that when my high beam is on it always outputs 100%. When the high beam sensor is off then it modulates the output so it is not on all of the time so it looks dimmer and this can be set by the remote fob.

Alternative solutions:

I just can't see the trouble of adding HID lights (TrailTech and other), not for my purposes. So I think this LED light is a good compromise for amps, lumens and cost.

There certainly are other LED lights around (like the dual LED setup Neduro had on his 2012 Dakar bike, using rectangular Dually D2 and Dually 2x2 LED lights from Rigid Industries: a pair of lights totalling 3900 lumens for $300 yet only drawing 2.9 amps! (35W draw!).

I have a lot more information on my G650X Links page (search for sanjoh).

Setup:

So my setup is to aim the LEDs just barely above the top of the low beam light thrown by the main H4 headlight bulb, then set the LED dimmer to maybe 30% of total brightness. This will make them last a long time as they won't overdrive them so much - I measured 0.25 amps for both of them (that's under 20% of the full 1.4 A).

And functionally it makes them perfect for more conspicuity in daytime as they are noticeable but not too bright which is a concern since they are aimed upwards a bit. So I no longer run on high beam all day long, plus I can use the high beam momentary flash button to then flash cars when they need my attention, which I could not do if I just left it on high beam all the time.

I rarely ride in traffic at night except when on trips, and the high beam then sets the LEDs to 100% which is quite effective. These are spot LEDs, not my first choice of floods, but OK. They also have a bit of light that spills out in a wider dispersion.

I highly recommend this setup using the dimmer as it solves all the issues - low current most of the time while on low beam, good daytime conspicuity but still aimed a little high so on high beam they aim properly.

Preparation:

I applied the Xpel clear lens protector to the glass lens.

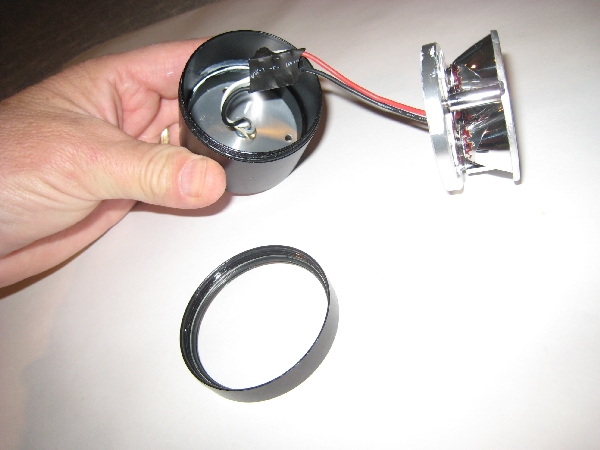

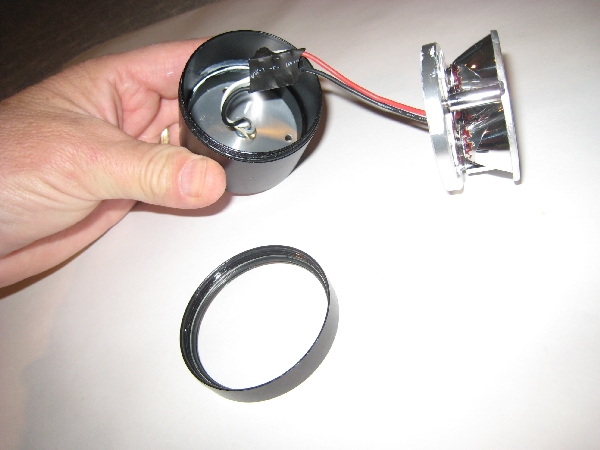

Heat concerns: On sanjoh's thread there was some discussion that heat was causing early failures of these LED lights (along with running at high current for a long time). I did a suggested quick fix for this by using a cheaper type of heat sink compound (RadioShack #276-1372) and took the LED front apart and applied a thin layer of the compound to the assembly.

(You don't need the expensive compound made for high temperature integrated circuit chips!) The goal is to conduct the heat from the inner LED assembly to the metal casing where air can cool it.

I don't believe the rear finned heat sink does much good at cooling this unit, based on the heat all being much further up front in the housing.

Upon reassembly I also coated the threads and the gap around the front lens with silicone.

Installation and Connections:

Electrical:

I used a Posi-Tap connector from Posi-Lock.com to tap off of the main fuse block from the wire coming from the "Fuse C" 7.5A (Low Beam), then thru an added inline fuse and to the input of the LED Dimmer module.

From my measurements, this circuit will have plenty of amps available, and it is further helped by the fact that the LEDs will only draw full current when switched to high beam, and the H4 main bulb low beam is then off and not drawing from this circuit.

The + output of the LED Dimmer goes through another added inline fuse then through waterproof connectors to the 2 LED lights (get waterproof connectors from sanjoh or I used Delphi Weatherpack weathertight connectors from Performance Plus Connection on eBay).

The purple input wire to the LED Dimmer is a sense input, so that when +12v is sensed it will always output 100% power (modulation) to the LED output feed.

I hooked this purple input to the high beam signal which I picked off of the headlight wire right at the headlight connector using another Posi-Tap. In addition just so no fault in the dimmer could damage the high beam I also ran this through an added small fuse on the way to the purple wire input to the LED Dimmer. Overkill I'm sure.

I got the inline fuses (with the LED that turns on if the fuse blows) from Radio Shack, and got a LittleFuse Mini Fuse assortment from Amazon.

I installed the LED Dimmer module using the supplied velcro, to the left airbox panel under the faux gas tank panel. Works fine there if carefully placed.

Mechanical:

Initially I installed this in the middle of winter when I was not riding the bike and was "out of touch" with it. As a result I installed it under the triple clamp. Well my stupidity became apparent on a Baja trip when the light would hit the fender on medium sized bumps of the fork! Duh. Stupid idea.

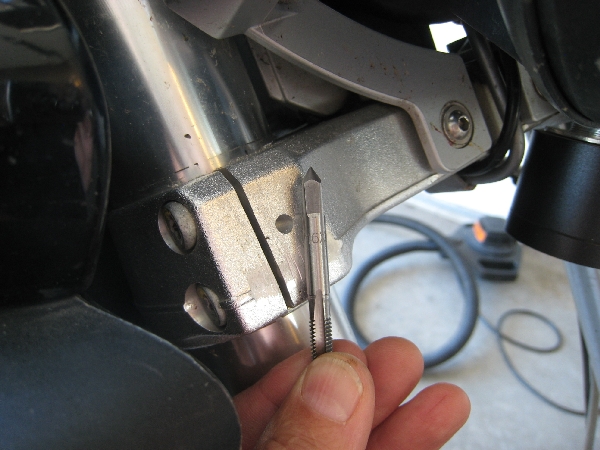

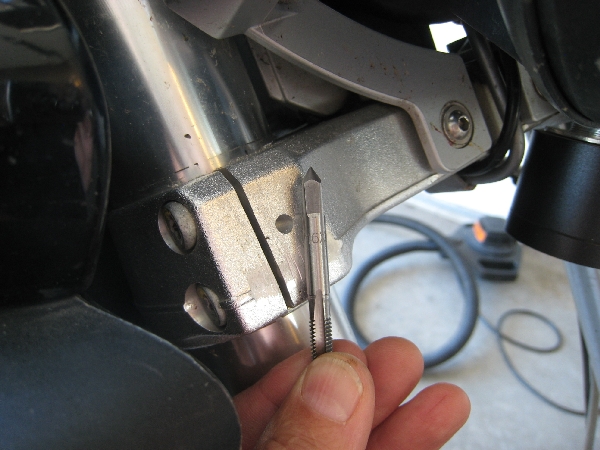

I did not want to install them up high on the handguards mostly because they would drown out the turn signals, so I decided there was so much material in the lower triple clamps that I could safely drill a hole in each one, centered between the 2 bolts and have enough depth to get several thread turns in there.

To do this I used a 6mm bolt. For the 6mm tap I drilled a 3/16" hole (.188") since it was aluminum (calls for 5mm (.197"). Was very careful not to go too deep and to not hit the fork. This worked fine actually. Just back out the tap a lot and clear the shavings while tapping.

One issue is that the lights tend to sag and drop down during normal use and especially off road. Even with the spacer tube for the bolt to tighten against it tends to droop. One thing I tried to do was to rough up the surfaces by adding a thin layer of epoxy to each side and this did help.

UPDATE:

After 4 years and around 20,000 miles including probably 3,000 off road (some on rough 4x4 roads), the "heavy duty" brackets failed me. One side sheared off completely and on the other I noticed there were serious cracks developing and they were about to break as well.

I ordered new heavy duty brackets and they too had some tiny cracks at the same location - where the sides were folded over. So I had a welder touch up the cracks with some weld beads. Too much would be bad as it really weakens the metal to heat it up so much, so only a small bead was added:

(End of update)

Daytime Conspicuity Pics:

The first 2 were taken at low beam, where I have the LEDs set MUCH below 100% fully on (PWM is used for Pulse Width Modulation). The best way to demonstrate this is to take daytime pics as I don't have a high end camera with manual exposure settings.

Since the LEDs are pulse width modulated, I believe it is pulsed from 100% On to 100% off so the PWM simply modulates the duty cycle of how long it is on at a time (0-100%).

So at a quick exposure level my camera either gets the LED full on or full off, so the pics below when they are on, they are fully bright, and brighter than the eye sees them when it integrates over time.

So much for my analysis. With the lights on low beam I took a bunch of pics and some show them being off and some on.

Low Beam:

High Beam:

These are on high beam, where I simply covered them with cardboard for the first pic.

More Pics:

Back

Back

Back

Back